Apple details new MacBook manufacturing process

In a press release touting the new manufacturing process, Steve Jobs said, “Apple has invented a whole new way of building notebooks from a single block of aluminum." (Watch the video)

Jonathan Ive, Apple’s senior vice president of Industrial Design, noted that, "Traditionally notebooks are made from multiple parts. With the new MacBook, we’ve replaced all of those parts with just one part—the unibody. The MacBook’s unibody enclosure is made from a single block of aluminum, making the new MacBook fundamentally thinner, stronger and more robust with a fit and finish that we’ve never even dreamed of before.â€

CNC unibody fabrication

The previous MacBook Pro uses a thin, bowl-shaped shell that has an internal skeleton to hold the internal parts together. The top bezel lays on top and is screwed in place on the sides and back edge. These pieces allow for some tolerance, requiring plastic gaskets to fit the components together snugly.

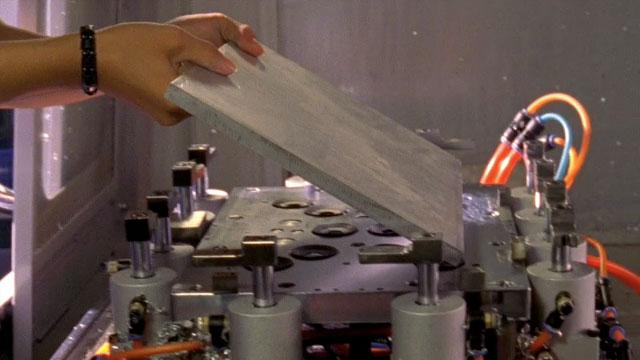

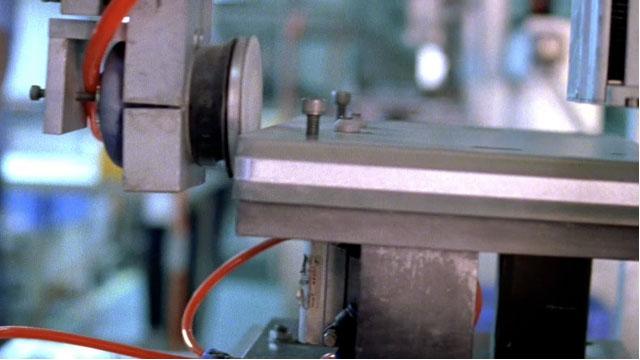

The new 15" MacBook Pro, along with its nearly identical 13.3" MacBook version, start with an extruded block of aluminum that is carved out using CNC or "computer numerical control" machines in a process used by the aerospace industry to build mission critical, high precision components.

The process starts with raw aluminum, selected for its favorable strength to weight ratio and the flexibility it offers in processing and finishing.

Extruded aluminum sheets are cut into blocks that undergo 13 separate milling operations.

Apple uses CNC to precision cut keyboard holes from the face of the slab (below top), mill out the "thumbscoop" that provides enough of a recession to open the display lid comfortably without putting too much pressure on the lid, machine out complex patterns from the inside (below middle) and perforate the speaker grill holes using lasers (below bottom).

A portion of the front edge is milled thin enough that a laser can be used to micro-perforate the metal to allow light from the sleep indicator LED to pass through the metal. When the sleep indicator is off, the metal appears to be solid. Apple has already used this process on the MacBook Air and the Bluetooth Keyboard that shipped last fall alongside the aluminum iMac.

Once the inside is precision cut (below top) leaving a design that is, as Ive observed, "in many ways more beautifully internally than externally", the edges are rounded and polished (below bottom).

The environmentally-friendly recycled bits

The material machined from the aluminum block is collected and recycled. Jobs noted that the new MacBooks "are the industry’s greenest notebooks.â€

Apple says the entire new MacBook line meets stringent Energy Star 4.0, EPEAT Gold and RoHS environmental standards, and leads the industry in the elimination of toxic chemicals by containing no brominated flame retardants, using only PVC-free internal cables and components, and using energy efficient LED-backlit displays that are mercury-free and made with arsenic-free glass.

Glass-faced, LED backlit display

The environmentally-friendly LED backlit display also offers other advantages; it turns on instantly when the display is opened as there is no warm up time required by a conventional cold cathode fluorescent lamp backlight.

It also requires less energy, allowing for 30% better efficiency while providing a brighter, more vivid display, or in the words of Bob Mansfield, Senior Vice President of Mac Hardware, "what you notice as a customer is that the color has a lot more pop."

Unlike the existing MacBook Pro, which houses the display recessed into an aluminum frame, the new design fits the display into a thinner lid and the entire inside face of the panel is covered with a single glass panel similar to the face of the iPhone, with a black margin around the display (below).

The new MacBook and MacBook Pro are detailed in:

Prince McLean

Prince McLean

Malcolm Owen

Malcolm Owen

William Gallagher and Mike Wuerthele

William Gallagher and Mike Wuerthele

Christine McKee

Christine McKee

William Gallagher

William Gallagher

Marko Zivkovic

Marko Zivkovic